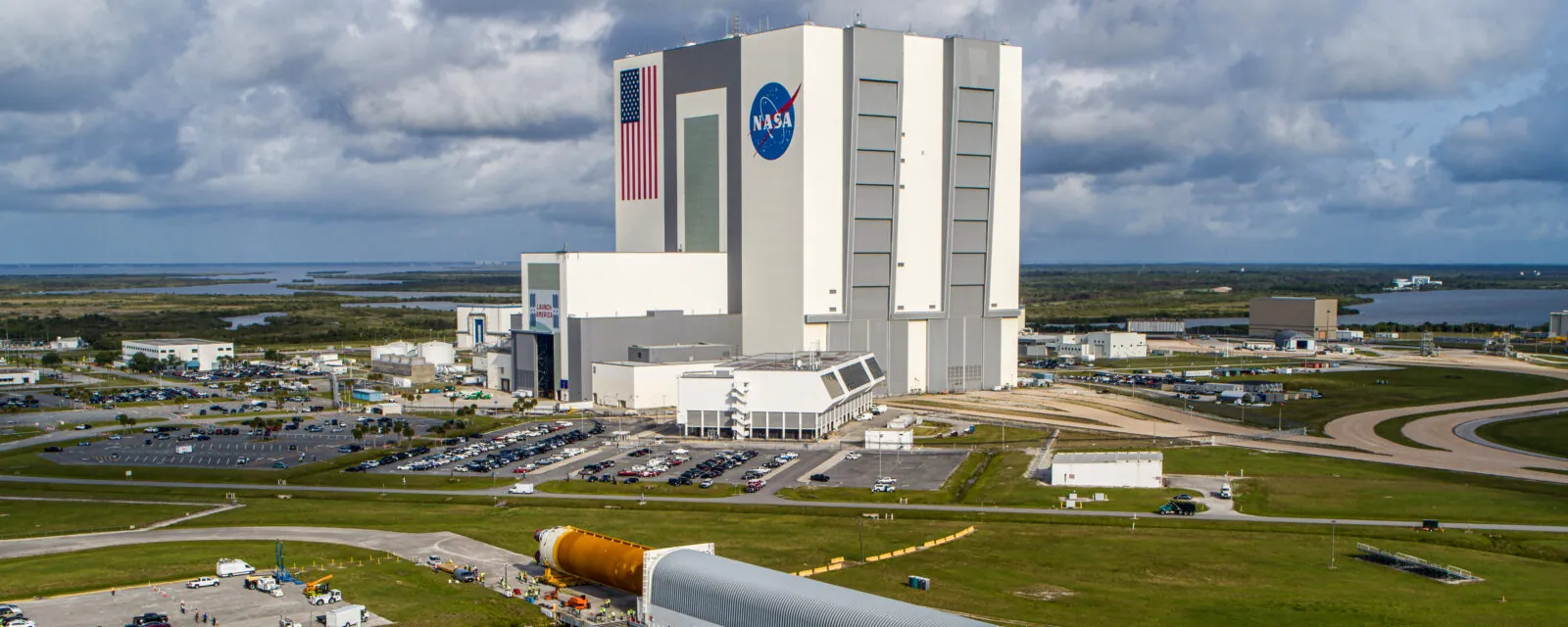

Vehicle Assembly Building Launch Vehicle Processing Facility – Kennedy Space Center

Project Details

Solutions

Location

Merritt Island, FL

Client / Owner

NASA

Kennedy Space Center

Focus Areas & Services

For over 55 years the Vehicle Assembly Building (VAB) at the John F. Kennedy Space Center (KSC) has been a mission-critical focus at RS&H. At 3,664,883 cubic meters, the VAB is the one of the largest (by volume) facilities in the world, uniquely designed to support assembly and integration of NASA’s massive launch vehicles and spacecraft for America’s Human Spaceflight programs. RS&H is honored to be a continuing part of the designs and modifications of KSC’s infrastructure as the Space Launch Systems Program prepares our nation’s Astronauts and spacecraft to return to space.

Approaching designs with the future of space in mind

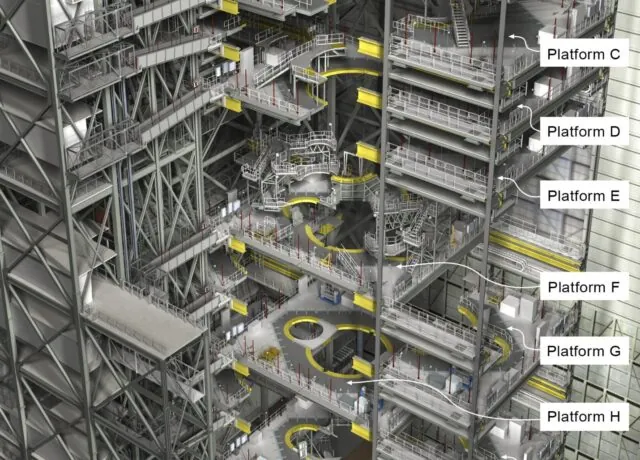

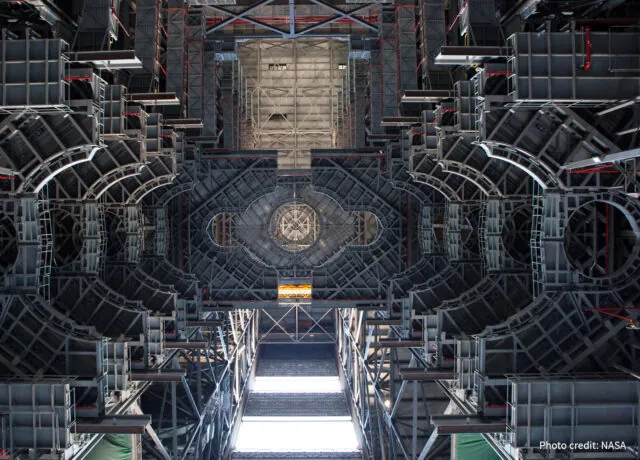

RS&H provided support to the Ground Systems Development and Operations Program through our design for upgrades to NASA’s iconic Vehicle Assembly Building (VAB) High Bay 3. Our design enables the stacking, processing, and testing of the SLS rocket and Orion spacecraft atop Mobile Launcher I (ML 1) and eventually ML 2. RS&H designed 10 levels of work platforms (Platform A though Platform K) that are engineered to encircle the SLS vehicle at determined mating, testing and integration points along the vehicle. These platforms provide the ultimate flexibility beyond any other in the industry, saving significant time and money during the lifecycle of the program.

Support Hoist and Elevator Platforms

The design of four electrically driven hoists atop each of Tower’s E and F enabled the restacking of platforms from the initial installation heights, and even enabled reconfigurations during vehicle processing. The design enables any platform within the stack to be adjusted, without the interruption of others.

To compensate for vertical stacking changes, RS&H designed elevator platforms and associated hoists to be adjusted much like the larger vehicle platforms. The ability to adjust the dual-car landings for both access towers kept the elevators operational with minor to no programming adjustments between restacking of the platforms.

Construction Support

RS&H acted as NASA’s technical representative during the demolition, and construction efforts to build the platforms. All systems and subsystems were reviewed to ensure compliance with the design and functionality requirements. Final testing and check-outs were performed under the watchful eyes of RS&H’s design engineers and construction experts along with NASA personnel.

Photo credit: NASA