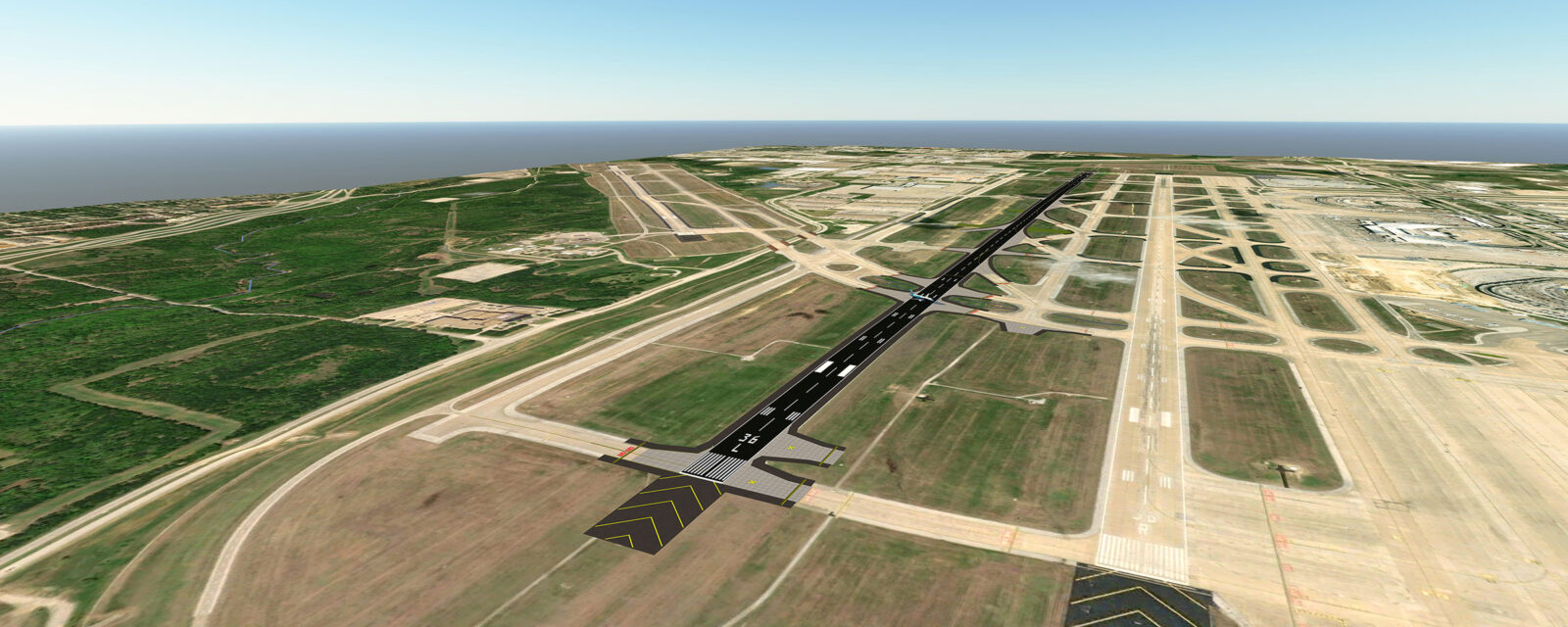

Dallas/Fort Worth International Airport Runway 18R-36L Rehabilitation

Project Details

Client / Owner

Dallas/Fort Worth International Airport Board

Cities of Dallas and Fort Worth

Focus Areas & Services

Size

43,500 square yards

Awards

Project Achievement Award, CMAA, 2022

Project of the Year, Dallas/Fort Worth International Airport, 2021

Designer of the Year, Dallas/Fort Worth International Airport, 2021

Minimizing impacts to provide a world-class travel experience

The Dallas/Fort Worth International Airport is a major economic engine for North Texas and welcomes more than 73 million passengers annually. In 2019, a pressing rehabilitation need emerged for the 2.5-mile-long Runway 18R-36L that facilitates approximately 140,000 arrival and departure operations each year. Closing a major runway for construction requires substantial planning, and construction needed to be completed quickly and efficiently to prevent major impacts to operations. As the airport’s prime design consultant, RS&H identified innovative solutions that minimized impacts so that the airport could continue to provide a world-class travel experience for its passengers.

Navigating unchartered waters during a pandemic

The design and construction timeframes were shorter than the norm, but the RS&H team met the schedule through significant preparation, collaboration, and communication. RS&H led a team of eight engineering consultants for the original bid package during the fast-track seven-month design phase and conducted 18 meetings (in addition to the numerous design meetings) to create a construction phasing plan that facilitated the safe operation of aircraft and minimal operational impacts.

The project began construction before the COVID-19 pandemic, but at the onset of the pandemic, airport staff considered postponing the project. RS&H’s team identified creative solutions that allowed nearly all planned improvements to proceed while achieving the project’s goals of preserving and extending the functional life of the runway, enhancing future functional performance, and reducing operational impact throughout construction.

Innovative safety, sustainability, & construction methods

After preparing the construction bid documents, RS&H also provided onsite technical services during construction. In addition to the pavement, numerous other runway elements needed to be rehabilitated, such as airfield lighting and storm sewers. The runway was improved by full-depth concrete repairs, totaling 34,000 square yards in the keel section and another 9,500 square yards in isolated slabs. The horizontal geometry was updated to connect 23 taxiways to meet the current FAA design criteria.

A first-in-the-state safety innovation was also incorporated on the runway, which included patented saw-cut grooves with a trapezoidal shape on the surface to reduce the risk of hydroplaning in the rain.

As the first Carbon Neutral Airport in the Americas, reducing its environmental impact is also a key goal of the airport. RS&H incorporated environmentally sustainable solutions into the project by requiring the concrete pavement panels removed from the runway to be crushed on site. The crushed material was then used as subbase for the runway and taxiway shoulders and no new materials were required. In addition, the plans included multiple infiltration strips the length of the runway to reduce impacts of stormwater sheet flow and improve water quality.

It was also critical to restore the runway and return it to service as soon as possible. Converting 28,000 linear feet (5.3 miles) of the project zone to landside space proved to be a key strategy.

“Taking that portion of the project out of the secure area expedited the process so they weren’t hung up getting through security,” explains Steve Creamer, Vice President of Aviation, RS&H.

The airport now has a revitalized runway that meets the needs of their operations and users for many years to come. The project was also recognized by the airport as its Project of the Year in 2021.