Building G – An Operation Warp Speed Project

Project Details

Solutions

Location

United States

Client / Owner

Confidential

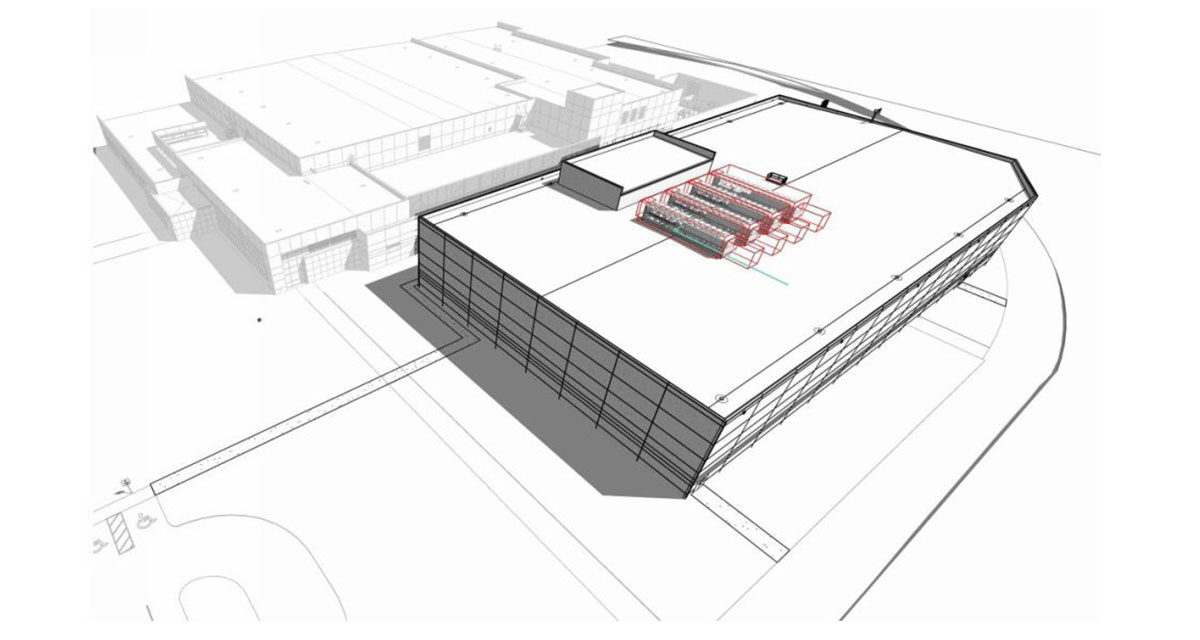

Building upon the success of the ground-up Advanced Development and Manufacturing Facility completed a few years prior to the COVID-19 pandemic outset, RS&H was tasked with expanding the existing facility. The project was part of the United States Government’s Operation Warp Speed, the partnership between the Department of Health and Human Services (HHS) and Department of Defense (DoD) aimed at helping accelerate the development of a COVID-19 vaccine. The 90,000 square-foot expansion, code named ‘Building G,’ was a design-build delivery project that required fast tracking every stage of the effort to meet the aggressive completion goal of 11 months, including full design of the ground-up building.

The client is a privately held, full-service Contract Development Manufacturing Organization (CDMO) servicing both government and commercial clients specializing in biologic drug substance manufacturing from the early stage through commercial production.

Mitigating manufacturing challenges by always being two steps ahead

The project objective was to have fill, finish, and package Biosafety Level 2 (BSL2) capabilities utilizing a flexible process that allowed for multiple products to be manufactured simultaneously. Procurement procedures were exercised early in the process and, even with the government issued directive that assured that building materials would first be directed to the project site ahead of non-emergency related requests, supply chain issues did arise, and delivery methods were adjusted accordingly.

The quick-turn demand forced RS&H to restructure the design process, focusing on functionality over a more traditional comprehensive design model, utilizing the most time efficient building construction processes. The steel package was issued ahead of the full design completion.

RS&H also answered the call for responsiveness by having personnel on the project site for the entire construction phase, substantially reducing the time needed to process requests for information and submittals. Project and team leaders held several meetings each week to make sure the schedule was maintained, and risks were properly assessed. The team was adept at identifying a Plan B for every step in the event it was needed.

Adding significant cold storage capabilities to the facility

With 60,000 square feet dedicated to Grade C production cleanrooms (capable of two 2,000L process trains per suite), media buffer preparation, formulation and filler capabilities, labeling, packaging, locker rooms, equipment storage and staging and an effluent decontamination system, the project added substantial cold storage capabilities to the client’s existing, adjacent facility. Ground floor functions are served by a 30,000-square-foot mechanical platform that houses the necessary air handlers, filter banks, boilers, CLO2 control room, WFI skids and tanks, and all of the electrical gear, including the full UPS backup. With each cleanroom designed to be exactly the same and provide all available utilities, a plug and play modular approach is created in the process.

Small community benefits from a prominent client

The client has been established as a national player in the biologic drug substance manufacturing industry, with facilities across the world. The client’s expansion of operations within the small community has been beneficial and seen as a huge success throughout by citizens and stakeholders.