New VAB High Bay 3 Platforms Ready for SLS

The Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center is a landmark like no other for the U.S. space program. The building served as the factory that churned out rockets destined for the moon and the reusable Space Shuttle.

Now, as NASA begins a new chapter of space exploration with an all-new vehicle, the VAB is again transformed.

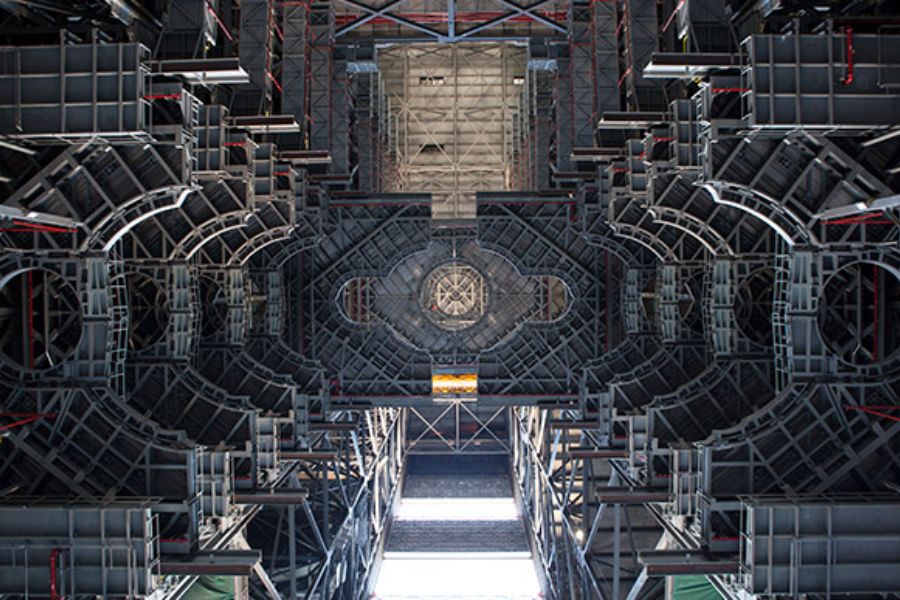

High Bay 3 is the first portion of the VAB to undergo the evolution to support the upcoming Space Launch System (SLS) rockets. Lessons learned by crewmembers who witnessed the transformation from the Apollo program helped guide the conceptual development of the form and function of the platforms that will now serve the newest, most powerful rockets in the world.

RS&H was engaged to design what others suggested would be impossible: a highly versatile, readily adaptable set of platforms, to meet the initial requirements of the SLS rockets as well as accommodate the vertical integration of various rockets in future spacecraft processing.

“We embraced the vision to be able to put platforms at virtually any position within the VAB on mounting rails,” said RS&H Senior Architect Alice Schultz. “The idea was that these platforms could be repositioned just like adjustable shelves in your home.”

Preparing for the Next Generation

Much like the Saturn rockets before them, the SLS vehicles could be assembled vertically in the VAB. Segments of the rocket would come into the Transfer Aisle, be lifted off of its transport trailer by a crane, and then positioned and stacked atop the Mobile Launcher base. However, the VAB can also accommodate an erector, where vehicle segments might be assembled via horizontal integration. Then the crane would lift the rocket and position.

For the assembly teams to be able to work on the SLS in High Bay 3, platforms have to be able to move in close, retract and re-connect as segments are added, and retract for the Crawler Transporter to move the rocket on the Mobile Launcher out of the VAB to the launch pad. SLS Block 1 vehicles are being designed for vertical integration, but elevations for mating vehicle segments and umbilicals will differ between each rocket.

Much of the facility had to be redeveloped, such as the custom steel shapes that were developed for the facility to serve NASA’s needs back in the 1960s. The 1960’s design used platforms, dead loads and locations based on the forefathers’ expectations of the next steps in space exploration.

The 2010 vision for the VAB drove the need to improve and expand the locations served and the concentration of loading. As a consequence, new platforms needed to be lean and versatile. Relocating, necessitated the kinetic–moveable, removable architecture.

A New Concept for Kinetic Architecture

The kinetic architecture allows for a completely relocatable, moveable system, including egress.

“It was a simple concept, yet it carried a complex set of requirements,” Schultz said. “For all platform systems to travel with the platform and be re-configured within hours, there were a lot of challenges to address.”

The biggest challenge may have been the addressing multiple moving parts that make up a platform bigger than a basketball court, weighing more than 30,000 pounds. The flexibility of the platforms requires the flexibility of the systems (electricity, fire protection, hydraulics, lighting, pneumatics, water, etc.) to be used by the platforms.

Depending upon where platforms are located, workers will be able to access platforms from level elevator landings. In the event of an emergency, however, everyone needs to evacuate to 2-hour fire-rated enclosure of the building’s stairs. To accomplish this, RS&H designed movable ramps and corridors to connect to the platforms, no matter where they may be positioned.

“The [initial] design was inspired by an airport jet way,” Schultz said. “The design of open ramps is similar to a boarding ramp or gangplank.”

Ready for the Countdown to Begin

In late 2018, NASA moved the Mobile Launcher with the Crawler Transporter into High Bay 3 of the VAB to do some additional outfitting of the mobile launch tower for vehicle services. NASA is aiming to launch the first exploration mission of the SLS in 2020.

The new generation of NASA space vehicles will be built on the foundation of rockets that were assembled in the VAB, which is perfect. After all, the VAB’s background and original vision – which included expansion capability and the expectation that things would need to change – still applies.

“High Bay 3 has been transformed and is ready for the next great steps because our forefathers got this right,” Schultz said. “At the same time, modern visionaries led this effort.”