A New Runway Spurs Adaptability, Collaboration and Patience

A new runway. And a complex project. Over my 34-year career working for the U.S. Army Corps of Engineers around the world, I have managed many multifaceted projects. None of those were quite as complex as the planning and day-to-day challenges of creating an office and providing the construction oversight and inspection services (Title II Services for those who speak DoD) for this 10,000-LF Runway reconstruction.

As we completed the eastern half of the runway and shift focus to the western half, I’ve reflected on how our team resolved challenges related to the native volcanic subgrade, local regulatory changes, distance, and supply limitations, and COVID hiccups. Working with the US Air Force and UK Royal Air Force clients, the Ascension Island Government (AIG), the construction contractor, and all stakeholders have required more than the ability to herd cats and spin plates – it’s required us to hone our skills of adaptability, collaboration, and patience.

Adaptability

Every year green sea turtles migrate 2,000 miles each way from Brazil to their birthplace on Ascension, laying eggs in nearly every square inch of sand on the island. Initially, a beach off-loading of the aggregate was planned which would have been much simpler. However, in the five years from the time of design to the start of construction, the significance of these beaches to these endangered turtles became more prevalent and this pier off-loading scheme had to be developed after the contract was underway. So, we developed a plan to offload the aggregate through the port, which required a lot of collaboration.

Collaboration

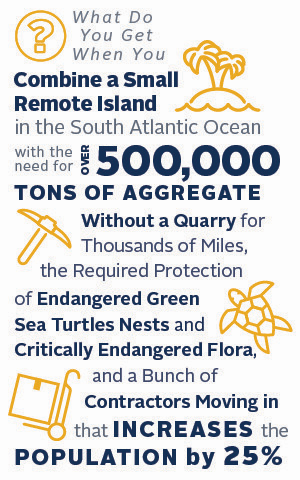

The project has required over 500,000 tons of aggregate – nine large ocean cargo ships worth. Traveling from a quarry in Nova Scotia, the trickiest part of the aggregate’s journey is the last few miles. It’s here where collaboration amongst multiple parties is critical. Because there’s not a deep-water port on Ascension, the ships anchor offshore and transfer 2,000 tons of aggregate at a time to a barge. Barges are negotiated through the shallow rocky water to the island’s only pier. Once there, the aggregate is offloaded onto a jack-up barge and then further onto a conveyor system that transfers it to trucks off the pier.

Before arriving, the aggregate must go through a substantial fumigation routine on the ship. Additionally, as it’s being off-loaded and again after it’s stockpiled, it must be checked at regular intervals for any hitchhikers that may be invasive to the island (ants, spiders, etc.). Such species would critically endanger flora. Both the off-loading and environmental inspections required extensive coordination with the AIG, the construction contractor, and the local population.

Patience

The challenge with aggregate off-loads is exaggerated by the fact that Ascension is located at a confluence of currents and winds that create massive ocean swells, frequently stopping any chance of getting barges close to the pier. The requirement to share the pier with other supply shipments coupled with winds, tides, and swells created additional coordination issues. Problems, such as cable breaks, snared tugboat propellors, and slipped anchors, frequently require implementing plans B, C, and D.

Once the shipped aggregate is offloaded, the larger (2-3”) rock is stockpiled and then sent through a rock crusher to make smaller sizes of aggregates (3/4” and down), which are then further blended as necessary to produce the concrete, asphalt, and runway foundation materials. Like every other piece of equipment for this project, the conveyors and rock crusher had to be shipped in, set up, calibrated, and maintained on the island just for this project – and then it will all be shipped back.

When the closest Wal-Mart and Home Depot are just over 5,000 miles away and Amazon only delivers once every two weeks aboard the Air Force C-17 supply flight, adapting to life and ensuring the quality of construction will provide Ascension with an enduring runway is tough. The team working on this project has coordinated daily with US, UK, and AIG officials, resolved issues with the construction contractor, collaborated to overcome design and logistical problems and coordinated alternate solutions when materials or procedures didn’t quite pan out all while maintaining personal relationships on a very small island. They have done this all in stellar fashion, and the Air Force has recognized this team with its highest government CPARS ratings possible.